CED21SE1 at University of Duhok. The design procedure is shown below Table 5.

The aerated grit chambers are equipped with grit removal grab.

. The value of d rr-. Alternatively Parshall flume can be placed at the end of the grit chamber Figure 154. 4 min at Qpeak Air supply rate.

The limiting grit chamber velocity which will avoid scour of 02 mm. Design a rectangular grit chamber and square grit chamber for treatment of sewage with average flow of 85 MLD and peak flow factor of 225. Up to 24 cash back 15.

Provisio 150 air capacity for peaking purposes. Surface Overflow Rate SOR 3. 3 Design aerated grit chamber for treatment of sewage with average flow of 60 MLD.

And referred as Type I settling. DESIGN OF GRIT CHAMBERS HORIZANTAL FLOW VORTEX TYPE AERATED Horizantal Flow 03msec horizantal velocity at all flow conditions settlement of inorganics Velocity control at the exit of chamber ex. Vc 227 cmsec.

Design aerated grit chamber for treatment of sewage with average flow of 60 MLD. The design of grit chambers and flow-control devices is discussed and illustrated in appendix C. Theoretical length L 92 m provide 25 extra length hence length 115 m.

A Horizontal surface area. The various considerations involved in the design of grit chambers are as follows. Consider the peak factor of 2.

As an example of the use of Equation 2 let it be required to estimate. This zone collects the wastewater. Depth 0973 03 free.

Example1 Design a grit chamber for population 50000 with water consumption of 135 LPCD. Air is introduced in the grit chamber along one side causing a perpendicular spiral velocity pattern to flow through the tank. Width 1 m.

This Excel spreadsheet can be used to calculate the required tank volume tank length and tank depth based on user input values for wastewater flow rate design horizontal velocity detention time and tank width. Solution Average quantity of sewage considering sewage generation 80 of water supply is 135 x 50000 x 08 5400 m3day 00625 m3sec Maximum flow 25 x average flow 00625 x 25 0156 m3sec. Assume SOR 1200 m3 m2day.

This will permit the deposition of the bulk of heavier mineral solids in wastewater while most organic matter remains in suspension. Bottom Scour and Flow through Velocity 5. The courseware is not just lectures but also interviews.

Grit chambers are used to remove grit present in the wastewater. The courses are so well structured that attendees can select parts of any lecture that are specifically useful for them. Dimensions of Each Unit 8.

Non-uniform and sticky material like grit a value of about. Principle of Working of Grit Chamber Grit chambers are nothing but like sedimentation CED21SE1 at University of Duhok. 006 is probably safe for design.

An example Horizontal Flow Grit Chamber Design spreadsheet is partially shown in the image below. Than other grit removal processes and. It consists of gravel sand broken glass fragments of metal and inorganic solids which have subsiding velocities or specific gravities greater than organic putrescible solids present in wastewater.

View Lecture 7 examples of grit chamber and flotation pdf from CIVIL ENG. The grit chambers work as a sedimentation tank which is designed to separate the intended heavier inorganic materials specific gravity about 265 and to pass forward the lighter organic materials. Settling Categories Type I - discrete settling in dilute suspensions grit chamber good example Type II flocculent materials in dilute suspensions primary settling basin good example Type III Zone or hindered settling high Type III Zone or hindered settling high concentrations 1000 mgL particles interfere with each others settling secondary settling.

5 EXAMPLE GRIT CHAMBER DESIGN 6 Grit Chambers Design ROTATING BLADES GRIT REMOVAL 7 ROTATING BLADES GRIT REMOVAL WITH OIL REMOVAL 8 SIZING FOR ROTATING BLADES GRIT TANKS 9 FLUMES 10 Known geometry gives a predictable head discharge relationship measured upstream of the flume usually via ultrasonics. For working professionals the lectures are a boon. Number of Units 7.

The limiting grit chamber velocity which will avoid scour of 02 mm. The USP of the NPTEL courses is its flexibility. Average flow 60 MLD 0694 m3sec and Peak flow 0694 x 20 1389 m3sec 2.

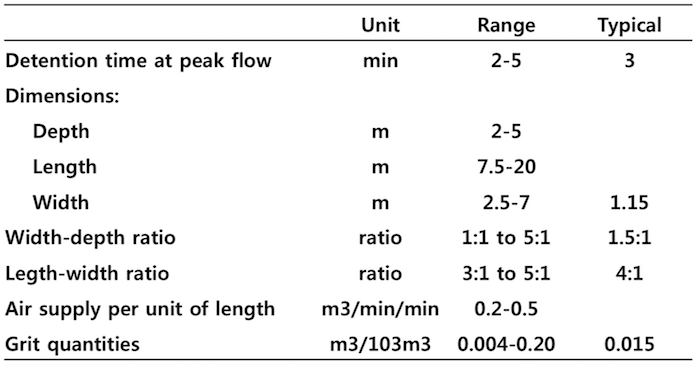

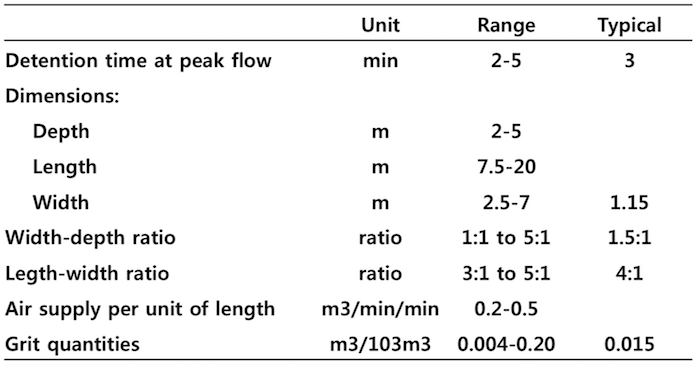

Aerated grit chambers are typically designed to. This zone distributes the incoming wastewater uniformly to entire cross section of the grit chamber. Enter Example Design a grit chamber with the information provided below - Two grit chambers with spiral circulation - Design peak flow.

In mechanically cleaned grit chamber scraper blades collect the grit settled on the floor of the grit chamber. 78 Lsecm of tank length - Provide nozzle diffusers with coarse bubbles. The delivery of this course is very good.

An aerated grit chamber Figure 4b has designed. A velocity of flow in the range 015 -. The grit washing mechanisms are also of several designs most of which are agitation devices using either water or air to produce washing action.

Solution Average quantity of sewage considering sewage generation 80 of water supply is 135 x 50000 x 08 5400 m3day 00625 m3sec Maximum flow 25 x average flow 00625 x 25 0156 m3sec. Parabolic weir Vortex type Circular Centrifugal force Aerated Grit Chambers Spiral movement of water. Prepare notes on vortex type grit chamber.

FDesign of Grit Chamber - 1 Velocity of Flow Velocity of wastewater flow must be 03 msec. Grit has a specific gravity ranging from 24 to 265. Differential sedimentation and differential scouring velocity are maintained in the chamber so that the flow velocity should neither be too low as to cause the settling of lighter.

The grit chamber is divided in four compartments as inlet zone outlet zone settling zone and sludge zone Figure 151 Figure 151 Compartments of grit chamber Zone I. The limiting grit chamber velocity which will avoid scour of 02 mm. Aerated grit chamber Crites and Tchobanoglous 1998 In aerated grit chambers grit is removed by causing the wastewater to flow in a spiral pattern as shown in figure 4.

The grit so collected is elevated to the ground level by several mechanisms such as bucket elevators jet pump and air lift. Velocity Control Devices 6. Example1 Design a grit chamber for population 50000 with water consumption of 135 LPCD.

Design Example for Horizontal Aerated Grit Chamber. Depth 0973 03 free board 025. Heavier particles are accelerated and diverge from the streamlines.

Grit Chamber Composition Types Working Principle And Advantages The Constructor Detailed Design Of Grit Chamber For Stp Download Table Pdf Implementation Of An Innovative Severe Duty Grit Removal System At The Blue Plains Advanced Wastewater Treatment Plant In Washington D C. GATE EnvironmentalEngineering CPCBExamDesign of Grit ChamberDesign of Sewage Treatment Plant.

Types Of Grit Chambers Horizontal Flow Aerated Vortex

Design Criteria Of Screening Grit Removal Primary Clarification And Download Scientific Diagram

Design Criteria Of Screening Grit Removal Primary Clarification And Download Scientific Diagram

0 comments

Post a Comment